Electric Wire Rope Hoist

Specification

Power supply: three phase

Rated lifting capacity: 1.5 - 120 tons

Intermittent rating: 63% rated load - 40%

Crane classification: ISO-M4-M5, FEM- 1M-2M Varies according to crane rating

Waterproof level protection: Crane IP54

Control box IP54

Push button switch IP65 with emergency stop

Motor insulation class: F class and thermocouple temperature control protection

Braking capacity: 150% of the rated lifting capacity of the crane

■ HOIST MOTOR

The electric crane adopts a 3-phase squirrel-cage induction motor with high performance, large starting torque, low current, lowest temperature rise, and quiet operation. It is also equipped with a constant temperature controller and an axial fan to prevent the motor from overheating and burning. The standard motor is F-class insulation, IP55 protection, and the load time rate is 40% ED. In addition, 60% ED motor and forced fan cooling can be selected to meet the use of high-frequency places.

■ HOIST REDUCER

The hoisting reducer adopts three-stage parallel shaft deceleration. The gear material is alloy steel with fine surface treatment. The hardness can reach above HRC60 degrees. It has high precision, low noise, long wear resistance life and simple maintenance.

■ HOIST BRAKE

The brake adopts DC disc type automatic adjustment safety brake system, which has good heat dissipation, strong braking force and wear resistance, and the non-asbestos pad can reach 1 million times under normal use. The simultaneous operation of the brake and the motor is really sensitive.

■ ROTARY METER BOX for UP/DOWN POSITIONING

Designed to ANSI/ASME B30.7, and EN 14492-2 standards. Two sections of upper limit (the first section cuts off the control, the second section cuts off the power supply) and one section of lower limit switch. There is another section of switch in each direction of the traverse trolley to prevent the danger of excessive movement of the wire rope over-winding or over-discharge. Convenient adjustment, easy maintenance, high precision and high reliability.

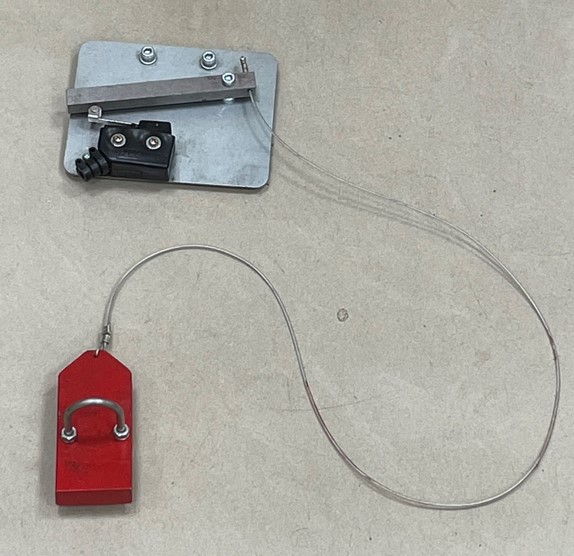

■ COUNTER WEIGHT LIMIT SENSOR provide over-winding protection when up/down limit sensor is mis-adjusted.

■ HOOK BLOCK

The hook is forged from S45C/SCM440, it can rotate 360° and is equipped with an anti-falling safety device, and the design of the cable pulley cover can prevent foreign objects from rolling

■ ROPE GUIDE

The standard product is equipped with a wire rope guide, the purpose is to ensure the correct alignment of the wire rope on the drum and to prevent the angle of the wire rope from being too large. The fairlead is made of high-strength plastic injection molding, and the plastic product reduces the loss caused by the friction between the steel cable and the fairlead, greatly improving the service life of the steel cable.

■ PUSH BUTTON

It adopts IP65 waterproof and dustproof buckle switch with emergency stop key, and a key switch can be set to filter crane operators.

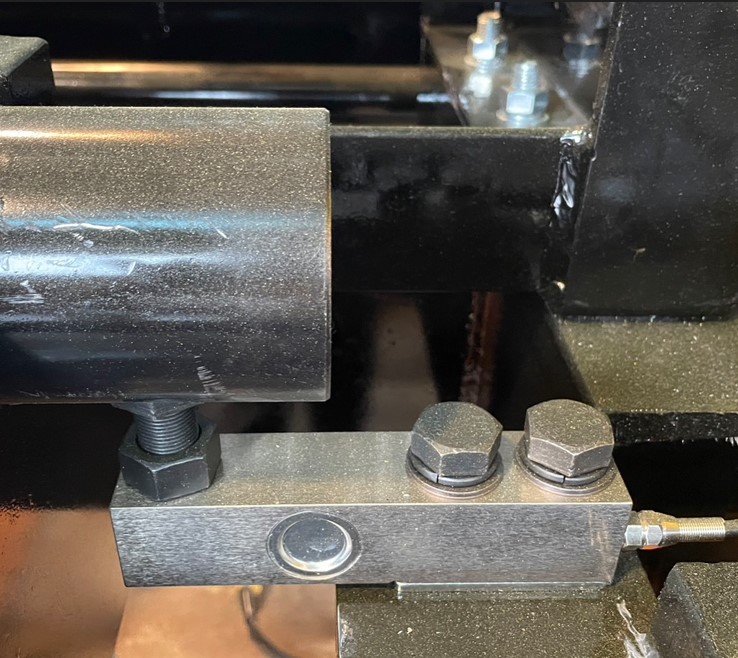

■ OVERLOAD PROTECTION

Load Cell and LED meter display provide precise and easy setting.

The standard product of THAC cable host is equipped with mechanical overweight protection device, which has high safety, good sensitivity, large adjustment range and easy adjustment. When the weight of the hoisted object exceeds the safety load set by the overweight protection, this device will prevent the hoisted object from rising and can only be lowered, and it also completely ensures the safety hazard caused by overloaded hoisting.

1) Precise Load Monitoring: A load cell is a high-precision sensor that can continuously monitor the load borne by the wire rope hoist. This accuracy helps ensure the accuracy of load protection under various working conditions, preventing exceeding the set load limits.

2) Real-time Feedback and Alerts: The load cell is equipped with an LED display setting gauge that can instantly show the current load status. When the load approaches or surpasses the predetermined limit, the setting gauge can issue alerts, notifying operators to be cautious and prevent loads from going beyond the safe range.

3) Enhanced Reliability: The digital monitoring capability of the load cell makes it more reliable compared to traditional mechanical spring screws. It remains unaffected by environmental conditions, temperature fluctuations, or usage lifespan, providing consistent and accurate load data.

4) Ease of Setup and Adjustment: Load cells typically have straightforward setup and calibration processes. Using the LED display setting gauge, you can easily configure load limits and make adjustments as needed to adapt to various job requirements.

In summary, the incorporation of a load cell can enhance the safety, reliability, and operational convenience of THAC electric wire rope hoist. Through precise monitoring and alert mechanisms, you can ensure that operations remain within safe load limits while benefiting from the convenience of automated monitoring.

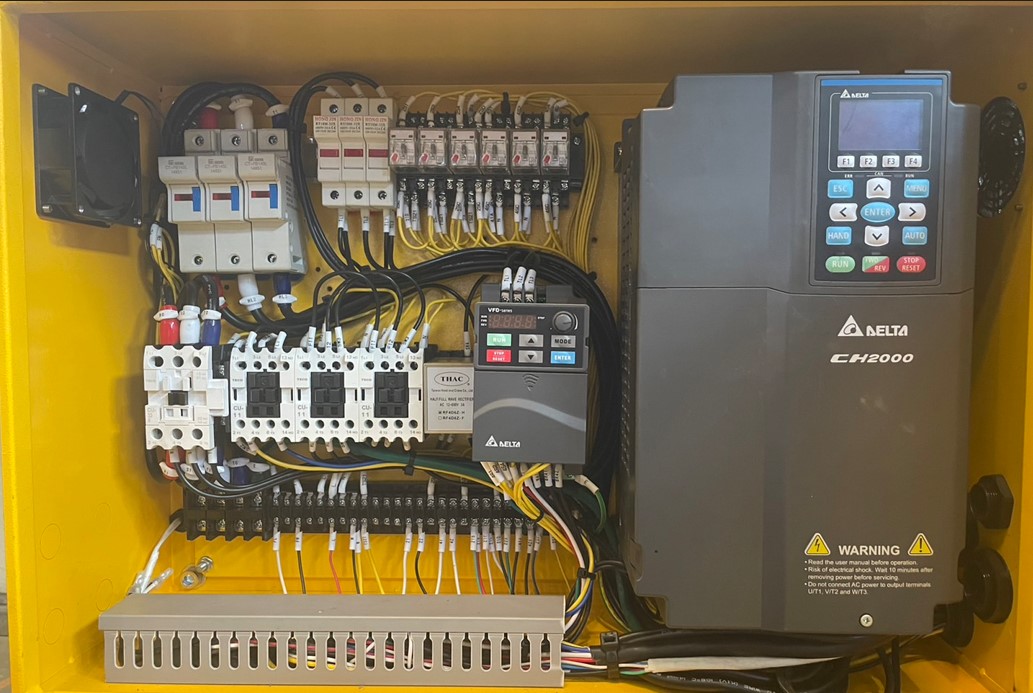

■ INVERTER SPEED CONTROL

The double speed of the THAC cable crane is controlled by a special frequency converter for cranes, and the ratio of fast and slow speeds can reach 1:10. It can also be controlled by stepless variable speed. The frequency converter setting makes the host more accurate when moving in all directions. The starting current is small and has protection functions such as over-current, phase loss, and reverse.. and so on.

■ OPTIONAL ACCESSORIES

A. Mechanical brake (drum overspeed protection)

B. manual release device

C. Electric control box quick connector

D. Load screen display

E. Wireless remote control

F. Hoisting 6:1 variable speed motor

G. Special high lift requirements

H. Room swing function

I. Electric power recovery system

DOWNLOAD CATALOG